“CLEAN” FISH SAUCE – FOR YOUR HEALTH

To cater to the diverse tastes of consumers, fish sauce manufacturers have developed a wide range of fish sauce products. So how do we choose fish sauce products that are safe for our family’s health?

So when buying fish sauce, how can consumers know the production of the product from the initial raw materials to fish sauce and bottling? We would like to share some production stages and quality control methods that Lien Thanh Fish Sauce Company is implementing.

Control employees in the production process. Ensure that people directly in contact with products during production must have good health according to requirements for food production and must be periodically examined according to regulations. Before entering production, it is mandatory to change labor protection and wash hands properly according to regulations

After being salted, the fish is transported to the factory to soak for 12 months before extracting the fish sauce. The soaking process is completely natural and is always monitored and checked for quality. The fermentation area is always kept closed and measures are taken to prevent harmful pests.

Packaging control Packaging must ensure safety when containing food and must be washed and sterilized before packaging the product.

– Lien Thanh Company

– Lien Thanh Company

When bottled, fish sauce must meet quality and microbiological criteria as required by the state and announced on the product label.

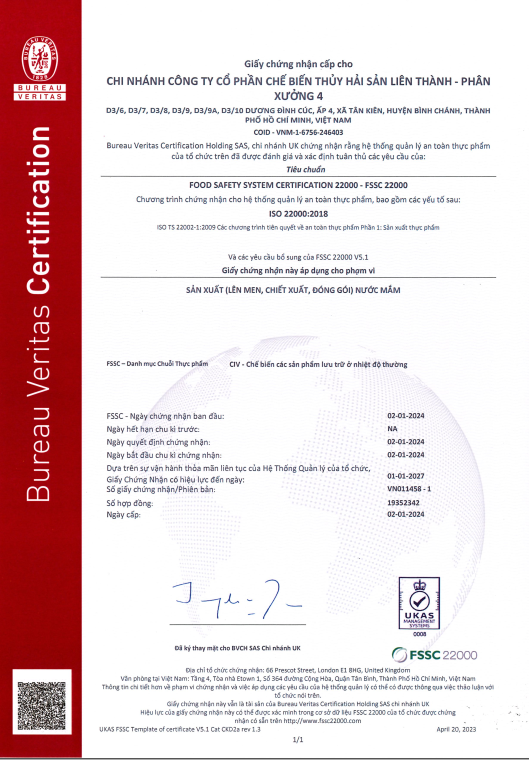

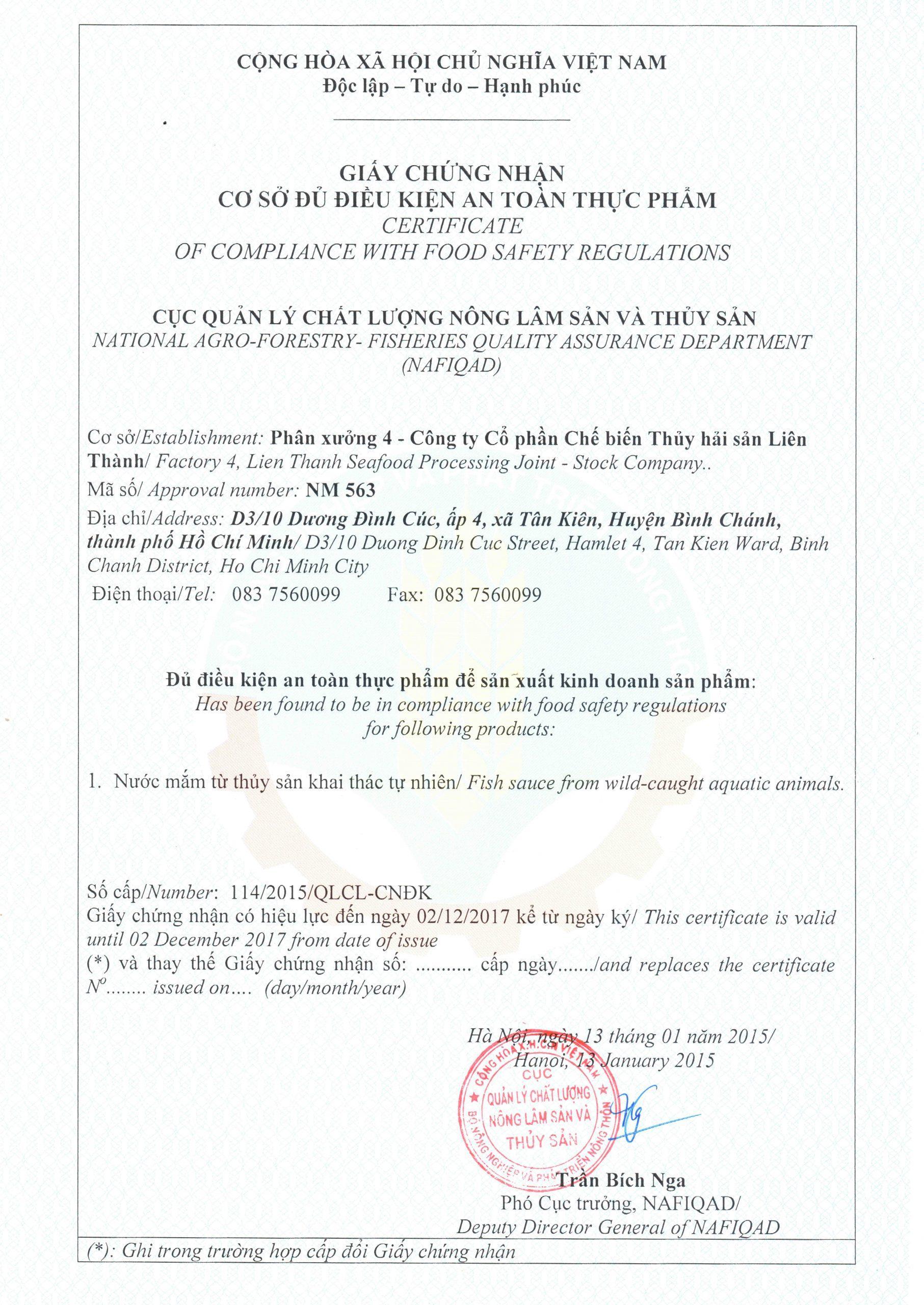

Products sold on the market always ensure traceability of raw materials. The Company’s production process as well as inspection and control measures are inspected and evaluated by state agencies and organizations. , independent and periodic monitoring to issue product quality certificates.

We strongly believe that a “clean” product like this will gain acceptance from many consumers, and will continue to be fostered by the 109-year-old Lien Thanh Company brand.